Design

CEECONS PROCESS Equipment Design is time tested in rugged process environments in FERTTILISER, POLYMER, PETRO-CHEMICAL,

REFINERY, BIO-MASS plants where the combination optimized power input efficient mixing are our routine.

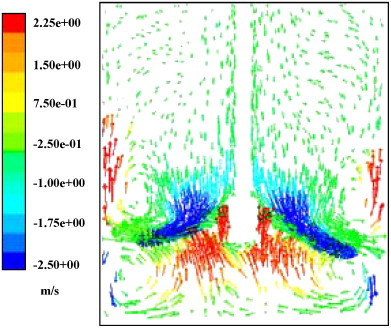

Every mixer is designed based on the process task it has to accomplish and power is optimized based on flow and shear.

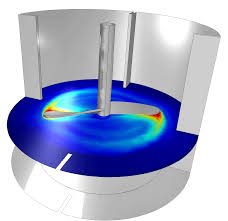

Synergy of 32 years of field experience and CFD technique enhances every critical mixer design and construction.

Our pre and post supply field survey ensure flawless process and mechanical Design and construction.

Process Tasks Handled :-

| Agglomeration | Mass Transfer |

| Blending | Ortho-kinetic Flocculation |

| Bingham Plastic Rheology | Polymerisation |

| Coagulation Peri-kinetic Flocculation | |

| Crystal Growth | Rheopectacy Rheology |

| Dispersion | Solid Suspension |

| Dialatant Rheology | Thixotropic Rheology |

| Emulsification | Viso-plasticRheology |

| Fermentation | Viscoelastic Rheology |

| Gassing | Hydrogenation |

| Heat Transfer | Homogeneous Mixing |