Impeller Models

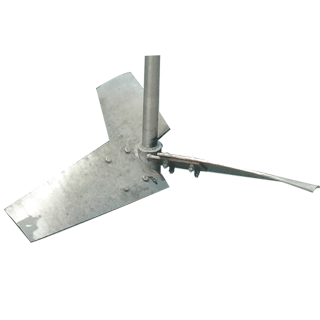

Aerofoil

- High Efficiency with varying twist and width from root to tip.

- Promotes pure axial flow from top to bottom and imparts more flow per unit power input.

- Excellent for Solid Suspension, Dissolution, Blending and Dispersion. Used in turbulent flow conditions.

- Three and four bladed versions are available.

- Saves 40% power for the same working conditions when compared to conventional pitched blade turbine impellers.

- Larger GS 2000 impeller can be accommodated in place of conventional turbines for the same motor power on account of its low power number.

- Speed Range : 80 to 500 rpm

- Dynamically balanced depending on requirement.

4 Bladed Anchor with Wall Scraper

- Operated close clearance with vessel wall or no clearance with wall scraper for promoting wall heat transfer in blending and heat transfer applications.

- Used in laminar and turbulent flow conditions.

- Also used in high viscous application with heat transfer by combining axial flow and high shear impellers.

- Speed Range : 5 to 70 rpm

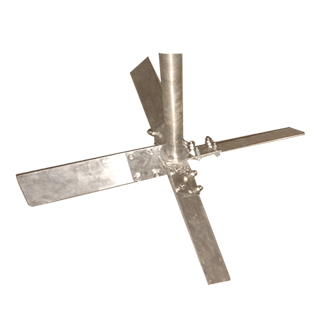

Pitched Blade Turbine

- Axial flow impeller for Blending, Heat Transfer, Dispersion and Solid Suspension applications in turbulent flow ranges.

- Available in Four and six bladed versions.

- Multiple impellers are used in tall tanks.

- Time tested.

- Speed Range : Moderate

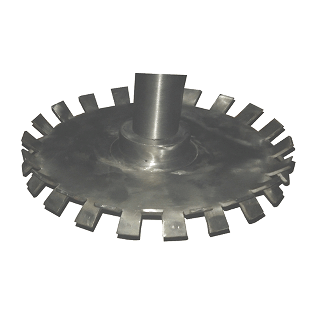

High-Shear-Saw-Cutter

- Best in the Speed Range of 1500 to 5000 RPM in laminar to turbulent flow.

- Creates very high shear for inducing inter molecular dispersion of immiscible fluids in emulsification and dispersion applications.

- Most suited for batch application..

Helix

- Designed with inner and outer flight for collinear counter-current pumping of materials of very viscous in nature ranging from 10000cp to 400000cp.

- Also combined with high shear Disperser in non-newtonian Rheopectic rheology.

- Effective even in low Reynolds number range.

Rushton Turbine

- Best for Mass Transfer and Gassing applications in turbulent flow regime.

- Most suited for gassing application when located above the gas sparger.

- The central disc diverts the gas bubbles towards the high shear zone near the blade corners to ensure shearing of gas bubbles and dispersion in fluid medium. This way formation of blurbs and geysers are averted by proper sizing.

- Also used in heat transfer applications. Consumes more power in un-gassed conditions, than in gassed ones.

Stator-Rotor

- This impeller is mainly used in emulsification, homogeneous mixing and size reduction process.

- High shear type with stationary work-head and close clearance rotor operating at high speed.

- Work heads are interchangeable.

- Used in batch operations.

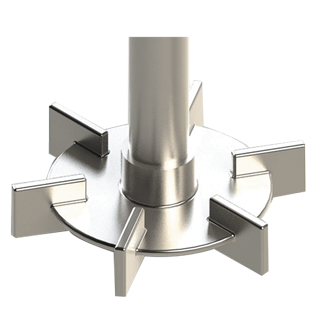

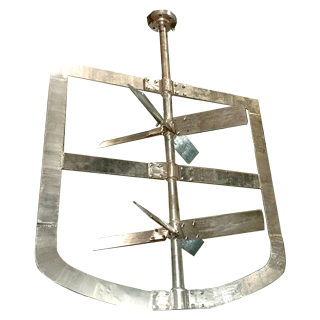

Anchor With PBT

- Contoured Radial impeller operated in close clearance to vessel wall or with wall wipers for convective heat transfer and blending applications.

- Designed with two or four blades depending on the process requirement.

- Changes in power response based on blade width, cross-arm and impeller H/D.

- Combines with axial and radial flow impellers in low viscosity ranges.

- Effective in viscosity range upto 50000cp.